.

At the beginning of each boat building project there will appear some questions,

whose answer have a large influence on the later shape of the finished boat.

The first question is for the intended purpose, from which depends a set of

requirements to the characteristics of a boat. Depending upon purpose of the boat

certain demands have priority opposite others. For example in case of designing a

speedboat the speed will be more important than a generous available space.

Usually however the special consideration of a characteristic involves compromises

regarding other characteristics. For example if a hull is designed rather long

and narrowly, its shape caused resistance is reduced and the attainable speed is

increased, at the same time the surface compared with a rather compact hull

increases and the friction resistance increases. If now the speed is the center

of attention, you will tend to a shape with a form resistance as small as

possible, because this increases with the speed in the square. Here already we

see that the optimal boat is a rather relative affair. Now possible building

methods and usable materials result from hull shape and size.

The building method of a boat is in close relationship with the selected or

available material and the possibilities of working on it. The oldest are wood

and animal skins. We can work with wood both in its original form and prepared

to timber materials e.g. plywood. It is suitable particularly for boats, which

weight has to be small, since it is to be regarded due to its structure as a

"micro framework", and framework constructions are characterised by high firmness

in relation to the weight. In most cases hulls can be made of wood without complex

moulds, which favours the production of single's buildings, since wood can be

brought with comparatively simple methods into almost any form, particularly in

connection with resins, like

epoxy .

Small hulls can be realized from wood as almost self-supporting constructions

with only few reinforcements e.g. frames, if they were built with glued plywood

panels or thin wood stripes (veneers) in different directions. Because wood is

porous and therefore water can get into it, a certain expenditure to prevent this

is necessary. The resins and coating systems today available do this if the

application is adequate, so we can make wooden boats, which are not substantially

more sensitive or maintain-more intensive than such from steel or plastic, unless

we select a clear lacquer finish due to aesthetic reasons. Outdoors, the best clear

lacquer can do nothing against the destructive effect of the UV radiation during

a long time, like in case of human skin each sun exposition leaves traces on a

long-term basis, a light protection factor in the coating can retard this, but not

prevent. In this case beauty has simply its price.

Steel as buiding material is important for boats starting from a certain size,

very small vehicles made of steel would have either a quite high weight or a very

thin shell, which would require a filigrane reinforcement similarly as in the

aircraft construction. Since in case of larger vehicles the levers and concomitantly

the tensions in the material become larger, steel with its high tensile strength

fulfills more the requirements. Contrary to wood, steel is available in comparatively

large dimensions, which causes a smaller number of seams e.g. while working with

panels. While the attempt to bring plywood panels into a shape curved in several

directions will cause the damage of the plywood if the curvature is too strong,

you can realize more curved shapes with steel panels, because they can be jolted

and stretched, which causes however a large effort of work.

Alternatively to steel

also aluminum can be used, whereby the lower weight cannot affect itself in every

case fully, due to the lower firmness it must be dimensioned more strongly.

Fiber-reinforced plastics have a far spectrum, concerning the relationship of

firmness and weight, it reaches from mixtures from polyester resins and cut glass

fibers sprayed into moulds to High Tech fibers such as kevlar laminated carefully

by hand. The latters we apply also in the wood epoxy processing.

A criterion for the selection of design and material which can't be neglected is

the effort of material and above all human work. From this point of view the chine

frame design has lots of advantages compared to curved frame design. A chine frame

shell consists first of two soil and side plates and a sternplate. If we

presuppose now the fact that the exterior surfaces of the hull permit a complete

surface development means this that the shell can be joined apart from internal

reinforcements from only five individual plate pieces. If we assume in additon

the fact that the "pattern" is certain before starting the building of the boat and

the plate pieces can be cut by an automat to its final shape, a substantially

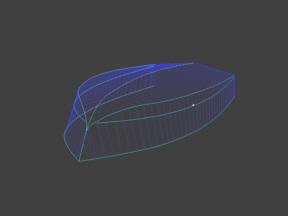

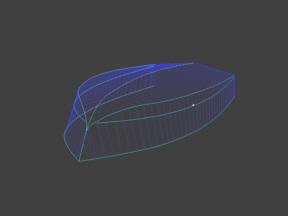

reduction of work expenditure results. For this purpose I developed a system of

algorithms, which can produce an accurate mathematical representation of a solid

consisting of several curved and developable surfaces. In practical application

these algorithms run as a LISP script in a commercial CAD application. By the

input of various parameters the characteristics of the designed boat can be

affected such as curvature of the lines, angles of the plates and naturally the

dimensions. The result is a three-dimensional model of the boat as well as its

developed surface. At the same time displacement, weight and their centers were

computed. In the three-dimensional model can be drawn construction details like

keel and frames up to the interior arrangement, which are cut afterwards like the

developed surfaces of the shell by automats based upon the computed file. This

procedure offers the following advantages: 1. Within a short time a row of drafts

can be made and optimized sequentially, time-expensive drawing and calculation

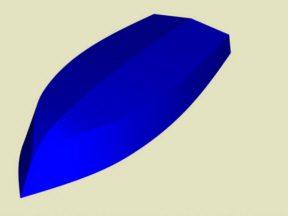

by hand is no more necessary. 2. By procedures such as Rendering and Raytracing

close-to-reality 3-D illustrations of the boat can be produced. 3. By the

connection of CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing)

the production both is more economical and more precise. 4. Since the applied

program produces consistently developable surfaces, which cannot be attained with

conventional methods, it is ensured that the prefabricated parts can

be joined to a boat

A criterion for the selection of design and material which can't be neglected is

the effort of material and above all human work. From this point of view the chine

frame design has lots of advantages compared to curved frame design. A chine frame

shell consists first of two soil and side plates and a sternplate. If we

presuppose now the fact that the exterior surfaces of the hull permit a complete

surface development means this that the shell can be joined apart from internal

reinforcements from only five individual plate pieces. If we assume in additon

the fact that the "pattern" is certain before starting the building of the boat and

the plate pieces can be cut by an automat to its final shape, a substantially

reduction of work expenditure results. For this purpose I developed a system of

algorithms, which can produce an accurate mathematical representation of a solid

consisting of several curved and developable surfaces. In practical application

these algorithms run as a LISP script in a commercial CAD application. By the

input of various parameters the characteristics of the designed boat can be

affected such as curvature of the lines, angles of the plates and naturally the

dimensions. The result is a three-dimensional model of the boat as well as its

developed surface. At the same time displacement, weight and their centers were

computed. In the three-dimensional model can be drawn construction details like

keel and frames up to the interior arrangement, which are cut afterwards like the

developed surfaces of the shell by automats based upon the computed file. This

procedure offers the following advantages: 1. Within a short time a row of drafts

can be made and optimized sequentially, time-expensive drawing and calculation

by hand is no more necessary. 2. By procedures such as Rendering and Raytracing

close-to-reality 3-D illustrations of the boat can be produced. 3. By the

connection of CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing)

the production both is more economical and more precise. 4. Since the applied

program produces consistently developable surfaces, which cannot be attained with

conventional methods, it is ensured that the prefabricated parts can

be joined to a boat

A criterion for the selection of design and material which can't be neglected is

the effort of material and above all human work. From this point of view the chine

frame design has lots of advantages compared to curved frame design. A chine frame

shell consists first of two soil and side plates and a sternplate. If we

presuppose now the fact that the exterior surfaces of the hull permit a complete

surface development means this that the shell can be joined apart from internal

reinforcements from only five individual plate pieces. If we assume in additon

the fact that the "pattern" is certain before starting the building of the boat and

the plate pieces can be cut by an automat to its final shape, a substantially

reduction of work expenditure results. For this purpose I developed a system of

algorithms, which can produce an accurate mathematical representation of a solid

consisting of several curved and developable surfaces. In practical application

these algorithms run as a LISP script in a commercial CAD application. By the

input of various parameters the characteristics of the designed boat can be

affected such as curvature of the lines, angles of the plates and naturally the

dimensions. The result is a three-dimensional model of the boat as well as its

developed surface. At the same time displacement, weight and their centers were

computed. In the three-dimensional model can be drawn construction details like

keel and frames up to the interior arrangement, which are cut afterwards like the

developed surfaces of the shell by automats based upon the computed file. This

procedure offers the following advantages: 1. Within a short time a row of drafts

can be made and optimized sequentially, time-expensive drawing and calculation

by hand is no more necessary. 2. By procedures such as Rendering and Raytracing

close-to-reality 3-D illustrations of the boat can be produced. 3. By the

connection of CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing)

the production both is more economical and more precise. 4. Since the applied

program produces consistently developable surfaces, which cannot be attained with

conventional methods, it is ensured that the prefabricated parts can

be joined to a boat